For professional electromechanical and electrical engin […]

For professional electromechanical and electrical engineering personnel, choosing wire and cable insulation material is an easy task. But for many ordinary users and people just entering the industry, it is necessary to understand. When purchasing, you should choose a suitable wire according to your own electricity load, and at the same time, you should also look at the raw material composition, model specifications, etc. introduced in the wire and cable manual, so as to reduce the occurrence of potential safety hazards and make the life longer. . Specifically, there are the following three points to pay attention to.

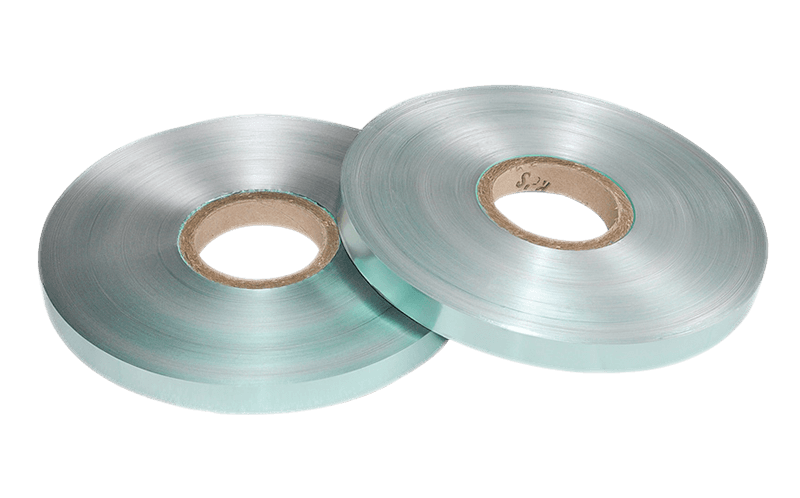

heat sealing single side 9AL/23PET/3PVC for cable

Type:Insulation Tape

Application:High Temperature

Tensile Strength:>20%

Supplier Feature:manufacturer

Originate time of factory:Year at 1992

Yearly output:Over 5000 Tons

Product Cutting Line:Over 4 lines

1. Wire appearance

When purchasing wires, consumers should pay attention to the appearance of the wires should be smooth and flat, the insulation and sheath layers are not damaged, the logo printing is clear, and there is no greasy feeling when touching the wires. From the cross-section of the wire, the thickness of the insulation or sheath should be uniform on the entire circumference of the wire, and should not be eccentric, and the insulation or sheath should have a certain thickness.

2. Conductor wire diameter

Consumers should pay attention to whether the conductor diameter is consistent with the cross section indicated on the certificate when purchasing wires. If the conductor cross section is too small, it is easy to cause the wire to heat up and cause a short circuit. Manufacturers of aluminum-plastic composite tapes recommend that household lighting line wires should be 1.5 square millimeters and above; household appliances with high power such as air conditioners and microwave ovens should use 2.5 square millimeters and above.

3. Standard use

The wiring should be standardized, and the BV single-core wire should be used for the fixed line to pass through the pipe. Be careful not to damage the wire when wiring, and do not damage the wire when decorating the room; do not connect in the middle of the same route; when the wire is connected to the electrical box (box) Don't touch the line.