Aluminum mylar is a type of Mylar that's coated with al […]

Aluminum mylar is a type of Mylar that's coated with aluminum foil to improve its barrier properties and make it more reflective. It can be screen printed, doming, or digitally printed, and is often used to create nameplates, labels, and tags for household and commercial use. UL (Underwriters Laboratories) approval is usually required for these types of products, which means they must meet specific safety standards. Whether you're using Mylar to produce labels or other types of products, it's important to choose a UL-approved brand to ensure your product is safe to use in your home or office.

Mylar is produced by drawing molten polyethylene terephthalate (PET) onto a chilled surface. The film is then drawn biaxially, a process that requires special machinery. Once it's done, the film has high tensile strength, chemical and dimensional stability, transparency, gas and aroma barrier properties, and electrical insulation. It's used for everything from helium-filled balloons to food packaging, and was developed in the 1950s by Imperial Chemical Industries (ICI), Hoechst, and DuPont.

While Mylar is more durable than most plastics, it can tear if it's cut or scratched. To prevent this from happening, it's best to use a sharp knife or razor blade to cut Mylar and avoid using heat-based tools. It's also recommended to use a cutting mat to protect the surface you're working on from damage.

While foil is undoubtedly the most versatile and durable option, Mylar has its own set of unique benefits. For example, it's less expensive than foil and offers comparable barrier properties—although it's not as good at preventing oxygen from leaking in foods. Additionally, Mylar is more flexible than foil and is less prone to cracking with use.

Mylar can be laminated to other materials, including aluminum foil, to enhance its shielding capabilities and make it suitable for electrical insulation applications. This is often done in the construction of wire pair shielding layers for control cables or the outer conductor layer of coaxial cables.

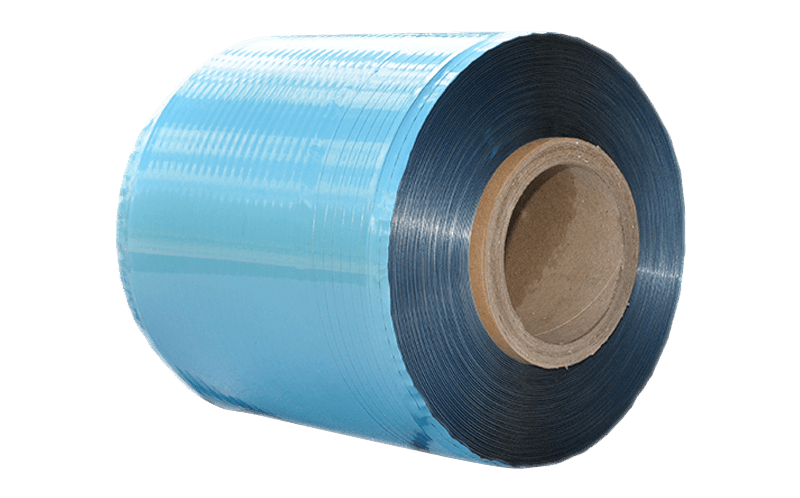

If you're interested in purchasing a roll of Mylar, it's important to find a supplier who offers a wide range of options and sizes. Our company will offer both aluminized and regular Mylar, as well as other materials like clear PET and LDPE, so you can choose the right thickness and width for your project. In addition, they'll provide fast turnaround and competitive pricing.