Innovation in the field of packaging has taken a giant […]

Innovation in the field of packaging has taken a giant leap forward with the introduction of metalized film. This cutting-edge material combines the advantages of traditional plastic films with the striking visual appeal and functional properties of metal, making it a game-changer in various industries. From enhancing product aesthetics to improving shelf life and sustainability, metalized film is revolutionizing the way we package, protect, and present goods.

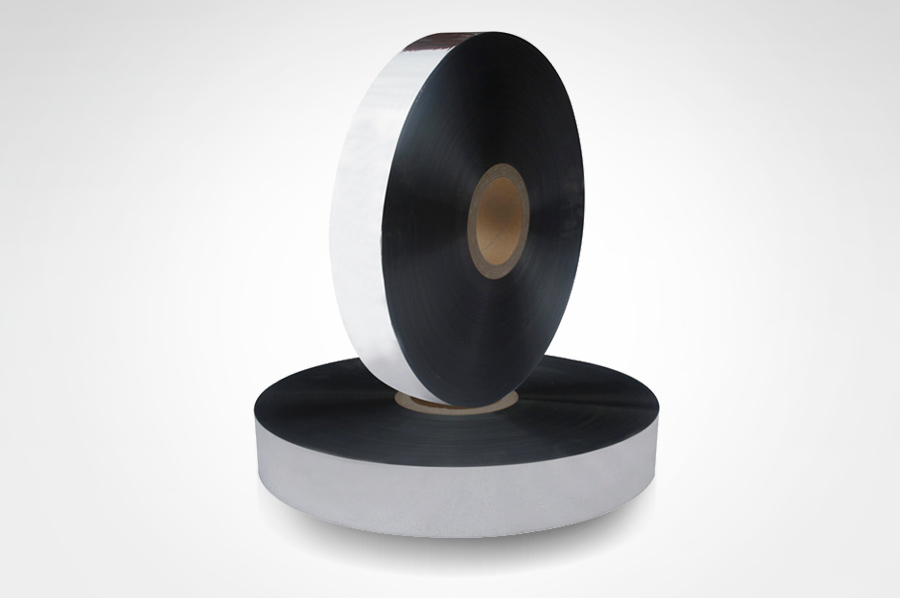

Metalized film is created through a process called vacuum metallization, where a thin layer of metal, typically aluminum, is deposited onto a plastic film substrate. The resulting film retains the flexibility and versatility of plastic while acquiring the lustrous appearance and reflective properties of metal. This unique combination offers numerous benefits across different applications.

One of the primary advantages of metalized film lies in its visual appeal. The reflective surface creates a striking and eye-catching effect, instantly capturing consumers' attention on store shelves. This feature is particularly valuable in industries such as food and beverages, cosmetics, and consumer goods, where packaging design plays a crucial role in attracting customers and influencing purchasing decisions.

Beyond aesthetics, metalized film provides functional advantages. The metal layer acts as a barrier, offering excellent resistance to moisture, oxygen, and UV light. This protective property helps extend the shelf life of packaged goods by preventing spoilage, preserving freshness, and maintaining product quality. Additionally, metalized film offers superior heat-sealing capabilities, ensuring secure and tamper-evident packaging.

Furthermore, metalized film contributes to sustainability efforts in packaging. With growing environmental consciousness, manufacturers and consumers alike are seeking more eco-friendly alternatives. Metalized film meets this demand by being lightweight, reducing material consumption, and facilitating recyclability. Its barrier properties also help minimize food waste by extending the shelf life of perishable products, thereby reducing the environmental impact of food packaging.

The versatility of metalized film extends beyond packaging applications. It finds utility in various industries, including automotive, construction, and electronics. In automotive applications, metalized film is used for window tinting, reducing heat and glare while enhancing privacy and aesthetics. In construction, it serves as a vapor barrier, preventing moisture penetration and improving insulation properties. In electronics, metalized film acts as a protective layer in capacitors, shielding sensitive components from electromagnetic interference.

As technology advances, so does the potential of metalized film. Research and development efforts are underway to enhance its properties further. Scientists are exploring ways to create thinner metal coatings without compromising functionality, enabling more efficient use of materials. There is also ongoing exploration into utilizing different metals and alloys to impart additional properties like conductivity or antimicrobial characteristics.

In conclusion, metalized film represents a significant leap forward in packaging and beyond. Its unique combination of visual appeal, functional properties, and sustainability make it a versatile and valuable material across industries. As we witness further advancements in manufacturing techniques and material science, metalized film is poised to continue transforming the way we package, protect, and present products, catering to evolving consumer demands while promoting a more sustainable future.